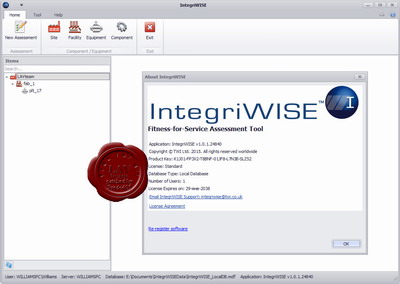

TWI IntegriWISE v1.0.1.24840

TWI’s IntegriWISE fitness for service software is a comprehensive tool for managing and assessing plant integrity data. The software has been designed to operate with the flexibility of a stand-alone application, or the power of centralised server architecture. When it is implemented through a server, IntegriWISE can be used as a central repository for all integrity-related plant information, with the ability to record and track key design and operating data, facilitate integrity assessments, and provide traceability for integrity management decisions. As a stand-alone application, individual users have the flexibility to carry out ad-hoc calculations and analyses.

Key highlights

automates Level 1 and Level 2 Fitness for Service (FFS) assessments described in API 579/ASME FFS-1

all assessments are rigorous applications of a selection of the most widely used and relevant FFS standards or procedures from API and ASME (e.g. API 579-1/ ASME FFS-1 2007, ASME B31.G)

material databases from the following design codes are included in the software: ASME VIII, ASME B31.3, ASME B31.4, ASME B31.8, PD 5500, API 650, and API 620

IntegriWISE offers the next generation in plant integrity management systems, by allowing engineers and managers to improve safety and plant availability and to reduce outage and maintenance costs

decision-support software designed to assist engineers in evaluating the integrity of pipework, pipelines, pressure equipment and high temperature structures

Key futures

wide range of assessment modules for different damage mechanisms including metal loss, pitting corrosion, laminations, hydrogen damage

wide range of equipment and component geometries including cylindrical shells, spheres, torispherical heads, elliptical heads, bends, elbows, reducers

calculation of critical operational conditions and safe continued operating loads to applicable international standards such as API 579-1/ ASME FFS-1 2007, ASME B31G, etc. in a single software tool

assessment management based on equipment with possible multiple assessments for each piece of equipment

a hierarchical structure enabling multiple assessments that can be used to conduct "what-if” scenarios

assessment reports generated in accordance with API 579-1/ ASME FFS-1 2007

future integration with TWI RiskWISE and CrackWISE software

users can undertake a `what if´ likelihood and consequence appraisal of each component, to determine the minimum level of inspection and maintenance, to mitigate the risk of failure and optimize the current inspection program

provides an indication of remaining life for all damage mechanisms, based on an implicit time dimension of risk (risk of failure generally increases over time) which is the only rational basis for setting safe operating periods between inspections